High Draught Bhatta

In India, we have been using fixed chimney type Bull Trench Kiln for brick manufacturing. There are newer technologies that are more energy efficient and cause lesser pollution. One such technology named fixed chimney Zig – Zag kiln .The Zig-Zag, Habla or the High Draught Kiln is similar firing technologies with essential variations in brick setting patterns where the kiln basic structure remains same. The principle followed in this family of kiln types is to prolong the travel path of fire. This high thermal efficiency of the kiln reduces fuel consumption by 25%. The earliest type of this technology was termed as Zig-Zag kiln developed in the early 1900s. Various reforms were also built which were relatively inexpensive variants adopted by small brick manufacturers. The design of this type of kiln ensures continuous operation of the kiln.

One of the more developed variant was The Habla Kiln. It was essentially an arch less zig-zag kiln patented in 1920 by British Engineer A. Habla. This had very wide and continuous open firing channels. Unlike zig-zag variants there were no permanently built dividing walls. Thus, the energy savings were higher. However the most important aspect of this kiln was that bricks could be loaded into the firing spaces through vehicular movement.

In Asian countries of India, Nepal, Bangladesh and Pakistan the High Draught or HD Kiln is the most popular technology of Zig-Zag firing. Their difference with European variation is the absence of any dividing walls. In the European variety of HD kilns, the length of the kiln gallery is increased by zigzagging the chambers and the fire follows a zig-zag path instead of a straight path followed in BTK. In the early 1900s, these types of kilns were widely used in developed countries particularly in Germany and Australia. In Europe, the interior cross-section of the kiln used to be small in original zig-zag kilns (7.5 ft wide x 7.5 ft high) and the kiln used to have 16-20 chambers each 20-25 ft long. Fan draught was provided and the kiln operated on high draught at a very fast rate of fire travel (50-100 ft per day).

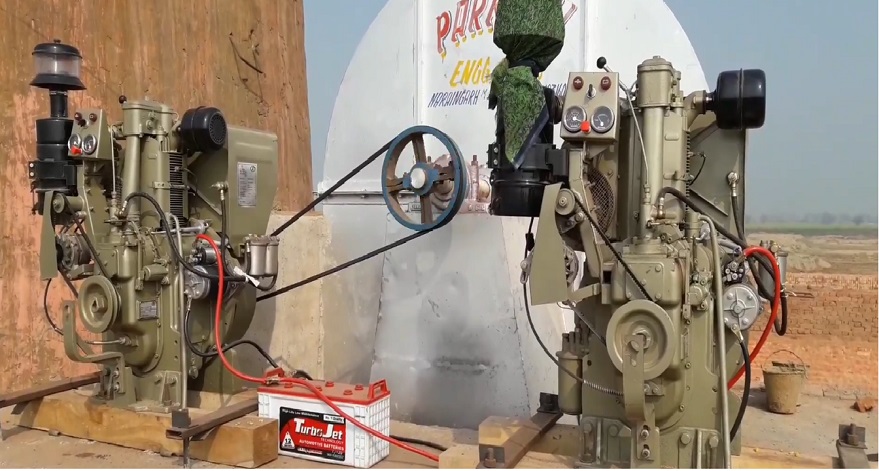

The High Draught or HD Kiln in India also follows the Zig-Zag firing concept. The Indian variation has several similarities with the Habla kiln. The kiln consists of a rectangular gallery which is divided into 24 chambers by providing temporary partition walls with green bricks. The wall of each chamber runs along the width of the gallery except one end, wherein a space of 60 to 65 cm is left for communication to next chamber. Draught is created by an induced draught fan with a 20-35 HP motor for proper combustion of fuel. Depending on the design capacity of a kiln, a chamber can hold 7,500 to 15,000 bricks. Normally, two chambers are fired per day and an output of 15,000 to 30,000 bricks per day can be obtained. When brought to full firing, the kiln operates on a draught of 50 mm hg.

The Hoffmann kiln is a series of batch process kilns. Hoffmann kilns are the most common kiln used in production of bricks and some other ceramic products. Patented by German Friedrich Hoffmann for brick making in 1858, it was later used for lime-burning, and was known as the Hoffmann continuous kiln. The first Hoffmann kilns were in the form of a great circular ring chamber, with massive walls and a large chimney at the centre, to which underground radial flues converged from the inside walls of each of the twelve chambers. The barrel-arched chambers (like a railway tunnel) have several small feed holes in the roof arches through which fine coal could be fed into spaces made among the bricks to be fired.

The Hoffmann kiln is a series of batch process kilns. Hoffmann kilns are the most common kiln used in production of bricks and some other ceramic products. Patented by German Friedrich Hoffmann for brick making in 1858, it was later used for lime-burning, and was known as the Hoffmann continuous kiln.

The first Hoffmann kilns were in the form of a great circular ring chamber, with massive walls and a large chimney at the centre, to which underground radial flues converged from the inside walls of each of the twelve chambers. The barrel-arched chambers (like a railway tunnel) have several small feed holes in the roof arches through which fine coal could be fed into spaces made among the bricks to be fired.

Around the outer wall or the kiln were the twelve openings for loading and unloading the individual firing chambers. These chambers were separated from each other by very large metal dampers that could be raised and lowered as the fire moved around the kiln from chamber to chamber.

Once the kiln is lit it is allowed to go out, and the sequence of operation is continuous. At regular intervals, the firing zone is moved forward and the corresponding changes made to the dampers between the chambers and into the chimney.

The chambers being loaded and unloaded move forward in sequence, and this way heat is extracted from the cooling bricks and also from the hot combustion gases. As the fire passes round the kiln, the chambers in front of the actual firing zone are gradually warmed, and the chambers behind cool off slowly.